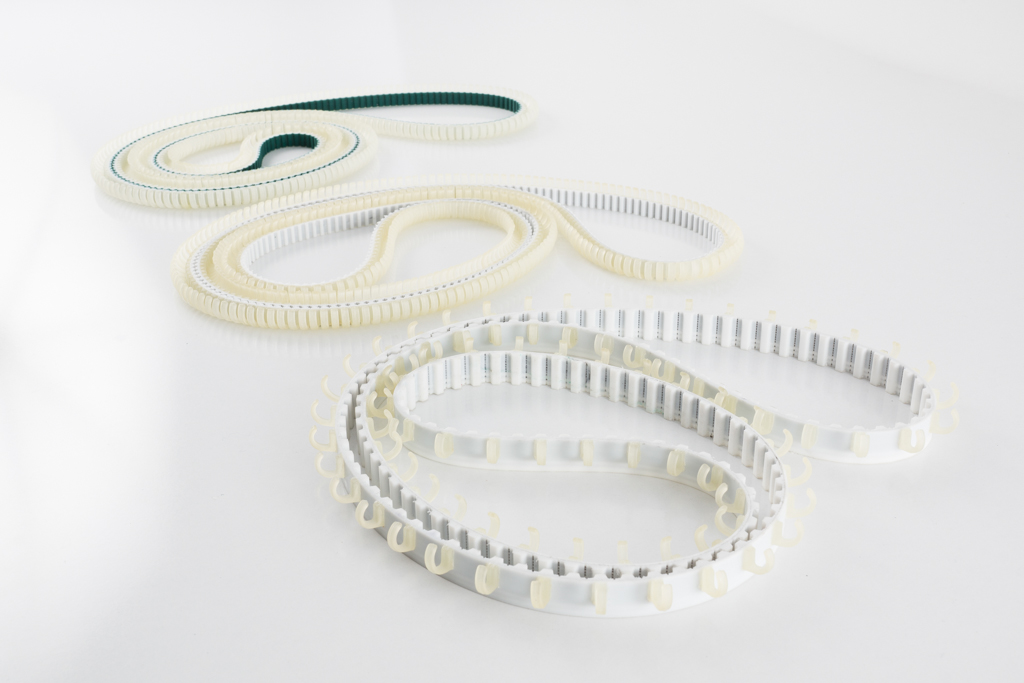

In the fast-moving world of food production, flexibility and efficiency are everything. Especially in biscuit packaging lines, product dimensions may vary from one production batch to another. This is where flexible “centipede belts” come into play.

Thanks to their unique shape and high adaptability, these belts can transport biscuits of different sizes without the need for belt changes. This not only saves time but also prevents production interruptions.

Why Use Flexible Packaging Belts?

- No Belt Change Needed: Whether you’re packing mini biscuits or large ones, the same belt can handle both sizes.

- Continuous Operation: No need to stop the line – production keeps flowing.

- Gentle & Precise Handling: The soft and flexible fingers grip the product gently, avoiding breakage.

- Highly Durable: Manufactured from wear-resistant PU with reinforced cords inside, they offer excellent longevity.

- Low Noise & Energy Consumption: Their lightweight structure reduces friction and energy usage.

📏 Adapts to Product Variety

These belts are also known as “centipede belts” due to their tooth-like profile. They can easily conform to different biscuit shapes and prevent slipping or jamming, even during high-speed operations. Whether square, round, or oval – the belt adapts.

🧼 Easy to Clean & Maintain

Made from smooth, food-grade materials, cleaning is quick and hygienic. The belts are resistant to moisture and cleaning chemicals, making them ideal for bakery lines.