Wide Timing Belts

It ensures precise timing, enhances positioning consistency, and mitigates issues arising from skidding and misalignment.

Gates Wide Timing Belts and Ortech Certified Belt Technologies in Collaboration

Gates Mectrol, the pioneer in wide timing belts, collaborates with Orhan Sanayi Belts, Turkey’s pioneering implementer of belt technology. Through specialized and certified solutions, we provide comprehensive solutions for every application involving wide timing belts.

SOLUTIONS

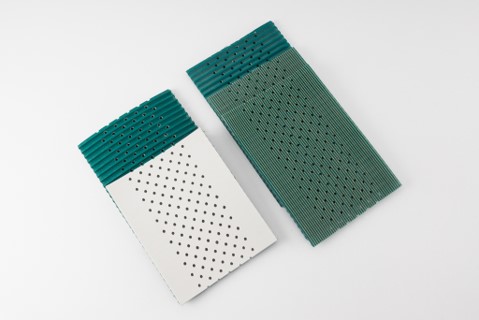

Ortech Silicone Coating

Advanced non-stick silicone coating technology of the 3rd generation

Developed after 5 years of dedicated R&D efforts, the 3rd generation specialized non-stick silicone coatings are now produced as a standard for wide timing belts, available in 5 different colors (white, black, grey, red, blue). Ortech silicone coatings stand out from the competition with various distinctive features.

✔ Odorless special formulation

✔ Standard production in 5 different colors

✔ Tear and cut-resistant structure

✔ Standard food compatibility

✔ Adjustable thickness

✔ No maximum height limitation

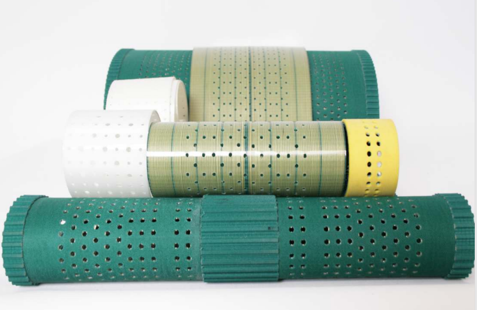

Vacuum Conveyors

Efficient, Accurate, and Sturdy – Extensive Production Capabilities

All your product requirements, including drilling, thread trimming, coating, and more, can be addressed at one convenient location—from stock to the final product. Leveraging computer-aided CNC machining technology ensures speed and precision. Gates polyurethane wide timing belts and auxiliary materials are entirely produced to European quality standards. Ortech vacuum conveyors stand out from competitors due to various features.

✔ Centralized European-quality production

✔ Diverse product range with Gates quality

✔ Precision machining through computer-aided CNC technology

✔ Quick delivery and production times (Contracted AirCargo option)

✔ 20 years of experience in the field

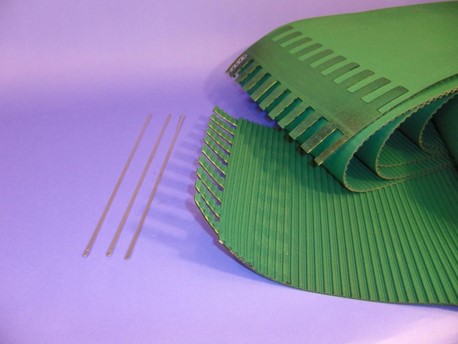

Profiled Wide Timing Belts

Revolutionary Solutions for Sorting and Transportation

Equipped with profiles, pallets, frills, and various features, our wide timing belts fulfill all the requirements for product transportation, sorting, and precise positioning. They provide innovative solutions, offering several advantages over conventional conveyors.

✔ Accurate positioning facilitated by the gear structure

✔ Swift stop-start and synchronization through the gear design

✔ Standard palette, profile, and frill options

✔ Superior craftsmanship employing advanced German welding technology

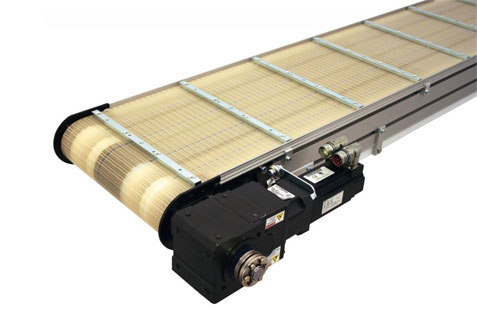

Effortless Installation Systems

Prepared-for-Installation Solutions to Streamline Maintenance Processes

Changing belt systems can often lead to extended maintenance times as various components need to be removed. Gates introduces a specialized technique designed to address these challenges, specifically tailored for wide timing belts. Widely favored in transportation applications, this method brings forth numerous advantages and features.

✔ Reduction of assembly time to 10 minutes

✔ Applicable to WT10, WH(1/2”), and WHTD8M belts.

✔ Standard cloth and clothless options

✔ Ready-to-install open-ended special structure that can be closed

✔ Innovative stainless flat pin design

Extensive Product Range

Gates polyurethane wide synchronous belts come in 5 different tooth profiles, featuring 2 distinct polyurethane filling materials and Kevlar/Aramid cord. Standard options include cloth-treated teeth and backing.

Standard Thread Forms

WT10 – WH(1/2”) – WT5 – WHTD8M – GMT3M

Expert and Innovative Solutions

Leveraging OSK’s two decades of expertise in belt processing, we provide a range of standard applications. From silicone coating to precision drilling and from easy assembly solutions to profiled wide synchronous belts, we offer professional and innovative solutions. Our knowledge and experience extend to providing application engineering services for both machine revisions and new manufacturing processes.

Quality, Precision, and Swift Production

As the “Authorized Manufacturer of Gates Polyurethane Timing Belts” in 2007, OSK ensures the production of products with European quality and precision. Utilizing computer-aided CNC machines and a team of experienced and qualified personnel, we prioritize efficient and accurate manufacturing. With a substantial stock ready for production, we enable swift delivery of your products through streamlined production processes.

Reliable, Experienced, Accurate, and Knowledgeable

Leveraging 40 years of product and application experience, OSK is dedicated to serving its customers in belt systems. Providing the most precise products and solutions, the company offers reliable and accurate knowledge. Backed by a team of experienced and knowledgeable professionals, customers can swiftly access accurate information and effectively address queries and issues. The company’s application engineering infrastructure assists customers with technical calculations and tables. Through training activities, it contributes to the personnel training of customers in belt systems, design, product types, and maintenance and repair activities.

Solution-Oriented Customer Services

Orhan Sanayi Belts is committed to making a positive impact on its customers’ spare parts and product supply processes through solution-oriented process management. Recognizing that accessing products and services can sometimes be a challenging process for purchasing and technical units, the company’s primary objective is to offer swift solutions to alleviate customers in such situations. Leveraging deep technical product knowledge and 40 years of machinery and application experience across various sectors, the company produces tailored product and service solutions.