Conveyor

We provide our customers with services across 12 diverse product groups dedicated to transportation and conveyor applications. Our offerings encompass solutions for conveyor systems involved in sorting, conveying, washing, straining, saucing, pulling, and sorting, among other operations. Equipped with the necessary production capabilities, we stand ready to bring your specialized designs to fruition with utmost precision. Our extensive product range caters to various requirements, including precise positioning, certification, and special features like antistatic properties, wipe ability, washability, and heavy load carrying capacity.

Select Your Conveyor Belt

Gates Synchro-Power® Endless Spliced Polyurethane

Gates Synchro-Power® Endless Spliced Polyurethane Timing Belts are crafted through the transformation of open-ended timing belts into endless ones using four distinct and specialized techniques. These belts find preference in straightforward transportation applications that involve frequent stop-and-go operations. They are available in various widths and come with different features to suit specific needs.

Bander PVC/PU Flat Conveyor Belts Belts

Bander PVC/PU Flat Conveyor Belts are versatile conveyor belts designed for general purposes, manufactured using PVC, polyurethane, silicone, and TPO materials with fabric layers. These belts offer a range of choices for working and carrying surfaces, making them suitable for a variety of conveyor and transportation applications. Their diverse structure allows for specialized options, enabling use in applications requiring washing or certification (FDA, ATEX, etc.).

Ortech Coated Belts

Ortech Coated Belts are produced by applying rubber or polyurethane coatings to flat belts using over 50 different coating materials. This method is chosen to impart various features to the belt, including grip, food compatibility, ease of cleaning, and resistance to temperature variations, depending on the materials being transported on the conveyor.

Esband Endless Carcass Flat Conveyors

Esband Endless Carcass Flat Conveyors are authentic endless carcass knitted flat belts featuring four distinct fabric options and over 20 covering material alternatives. The customizable and specially knitted carcass structure enables smooth operation, even on small-diameter pulleys. Versions designed for food contact compliance are also offered, ensuring optimal performance. The calibrated thickness of these belts prevents issues related to balance and errors.

Gates Food Compliant FDA Conveyors

Gates Food Compliant FDA Conveyors are monolithic/homogeneous conveyor belts crafted from thermoplastic polyurethane material, boasting FDA and EU certifications for safe food contact. Their preference over modular and fabric-layered tapes is due to their cost-effectiveness in terms of operating expenses.

Gates Superflex® Polyurethane Timing Belt

Gates Superflex® Polyurethane Timing Belts offer versatility, available in the desired tooth count with 5 different cords and various tooth profiles and pitch options ranging from ~1,500mm to 12,500mm. Their TPU and customizable structure make them a preferred choice for applications involving high-power carrying and pulling.

Ortech Shaped Belts

We produce uniquely designed profile/wedge/soldier components using TPU material, which are then welded onto the belts using four distinct welding techniques. This type of belt is often chosen for scenarios that involve pushing, stacking, clamping, or precise positioning during transportation.

Ortech Vacuum Conveyors and Belts

In applications that require vacuum transport, it provides conveying solutions through timing belts, flat belts, conveyor belts, and special hybrid solutions. It is frequently preferred for applications that involve stop/go or high-speed transportation. It also allows materials to be conveyed in the air with precise hole positioning and gripping coatings.

Ortech Special Transport and Conveyor Applications

In cases where standard solutions cannot meet the needs of transportation and conveyor tasks, there is always a solution. We have successfully addressed various challenging issues, such as enabling precise positioning of slippery products like fish or solving complex problems, including the use of silicone belts capable of operating at 180°C.

Ortech Polyurethane Round and V Section Belts

Crafted from thermoplastic polyurethane material with cord reinforcement, available in perforated or plain variations, and offering more than 10 different hardness, feature, and color options. These belts present the optimal solution for uncomplicated transportation needs. With proper guidance rollers in place, they can be effectively utilized in rotating conveyors. Some versions are specifically designed for applications involving food contact, and they are also employed in straightforward power transmission tasks.

Ortech Polyurethane Pentacle-Hexagon Belts

Crafted from thermoplastic polyurethane material with cord reinforcement, available in perforated or plain variations, and offering more than 10 different hardness, feature, and color options. These belts offer an ideal solution for straightforward transportation tasks. With their diagonal structure, they can effortlessly convey products without causing damage or leaving marks. Additionally, they find applications in basic power transmission operations.

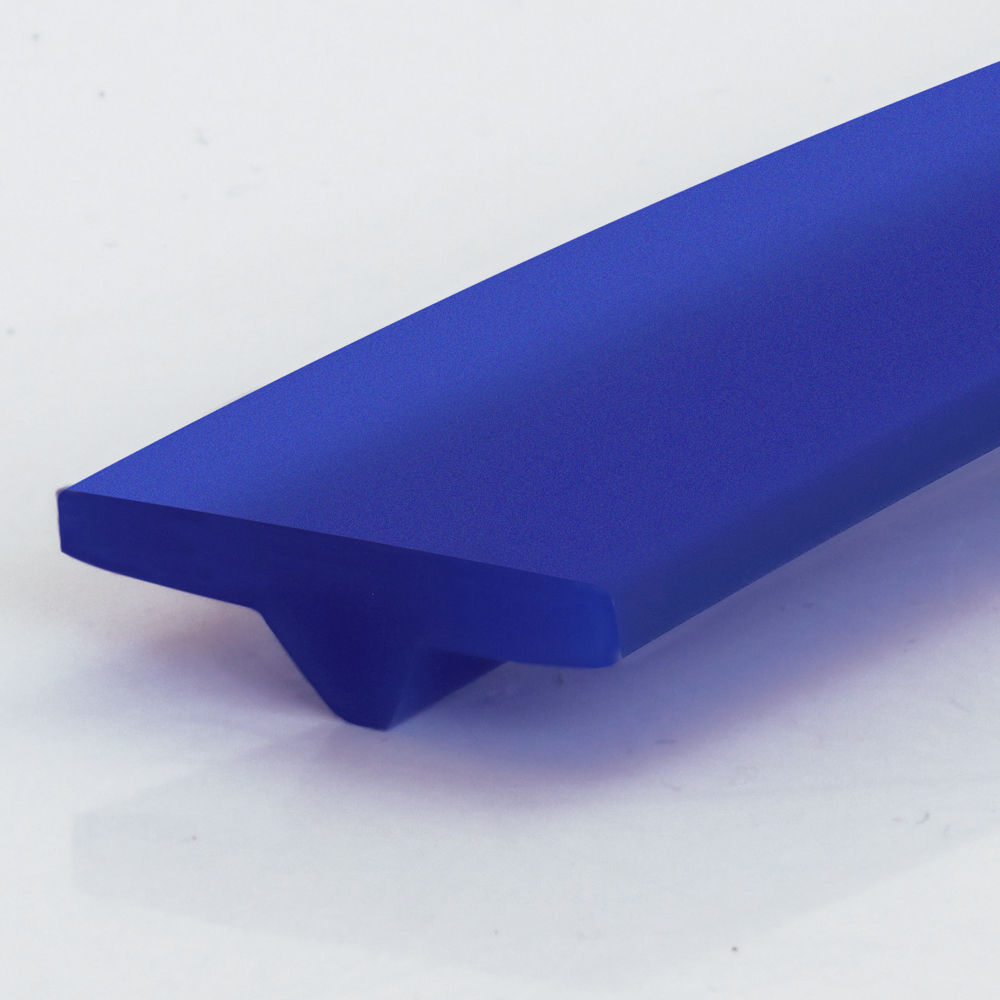

Ortech Polyurethane T Profile Belts

These belts can be custom-manufactured in the desired form and shape using thermoplastic polyurethane material. For those with a flat top surface, surfaces can be shaped, patterned, and even coated. Certified versions suitable for food contact are also available.

Reliable, Experienced, Accurate, and Knowledgeable

Leveraging 40 years of product and application experience, OSK is dedicated to serving its customers in belt systems. Providing the most precise products and solutions, the company offers reliable and accurate knowledge. Backed by a team of experienced and knowledgeable professionals, customers can swiftly access accurate information and effectively address queries and issues. The company’s application engineering infrastructure assists customers with technical calculations and tables. Through training activities, it contributes to the personnel training of customers in belt systems, design, product types, and maintenance and repair activities.

Solution-Oriented Customer Services

Orhan Sanayi Belts is committed to making a positive impact on its customers’ spare parts and product supply processes through solution-oriented process management. Recognizing that accessing products and services can sometimes be a challenging process for purchasing and technical units, the company’s primary objective is to offer swift solutions to alleviate customers in such situations. Leveraging deep technical product knowledge and 40 years of machinery and application experience across various sectors, the company produces tailored product and service solutions.